VIRTUAL POWER PLANT

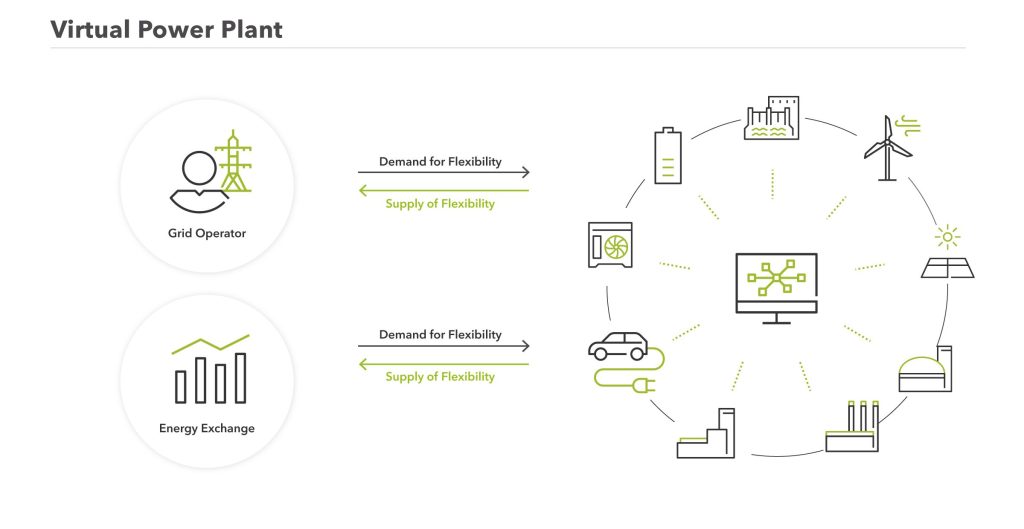

A Virtual Power Plant (VPP) is a network of decentralized, medium-scale power generating units as well as flexible power consumers and storage systems. Learn more about the purpose of this network and the technology that powers our VPP.

What is the Objective of a Virtual Power Plant?

Depending on the particular market environment, VPPs can accomplish a whole range of tasks. In general, the objective is to network distributed energy resources such as wind farms, solar parks, and Residential and Commercial grid-tie system, in order to monitor, forecast, optimize and trade their power. This way, fluctuations in the generation of renewables can be balanced by ramping up and down power generation and power consumption of controllable units. But the VPP not only helps stabilizing the power grids. It also creates the preconditions for integrating renewable energies into the markets. Individual small plants can in general not provide balancing services or offer their flexibility on the power exchanges. This is because their generation profile varies too strongly or they simply do not meet the minimum bid size of the markets.

By aggregating the power of several units, a VPP can deliver the same service and redundancy and subsequently trade on the same markets as large central power plants or industrial consumers.

Control System: High-Performance Data Processing

The control system is the technological core of the Virtual Power Plant. All assets, that are networked in the VPP, can be efficiently monitored, coordinated and controlled by the central control system. Control commands and data are transmitted via secured data connections which are shielded from other data traffic due to encryption protocols. The control system stores all the data needed to calculate the optimal operation schedules for electricity producers and consumers. These are for example:

- Actual power

- Readiness of the power plant or the power consumer

- Performance range for balancing energy

- Actual temperature (for example in a cold store)

- Water levels (for example for an industrial pump)

In addition to operating every individual asset in the VPP along an optimized schedule, the central control system uses a special algorithm to adjust to balancing reserve commands from transmission system operators, just as larger conventional power plants do. The bidirectional data exchange between the individual plants and the VPP not only enables the transmission of control commands. It also provides real-time data on the capacity utilization of the networked units. For example, the feed-in of wind energy and solar plants, as well as consumption data and electricity storage charge levels, can be used to generate precise forecasts for electricity trading and scheduling of the controllable power plants.

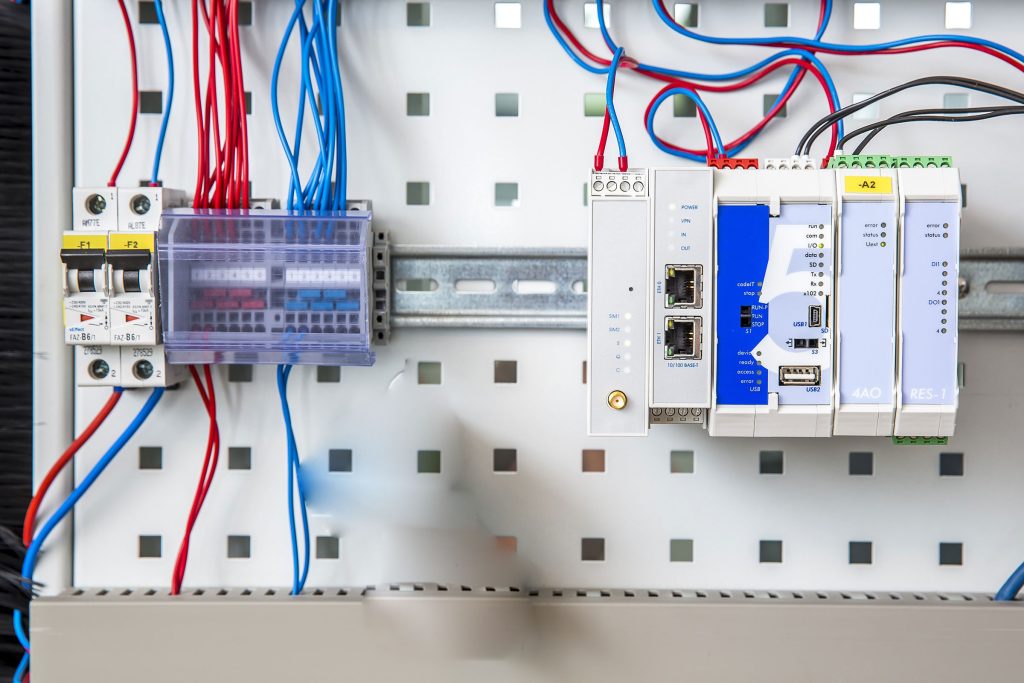

GTPower Gear: Secure Connection to the VPP

The GTPower Gear is a remote control unit, that allows to connect decentralized power producers and consumers to the control system of the VPP. The GTPower Gear connects the plants via a bidirectional, specially secured (tunneld) wireless connection by using the IEC 60870-5-104 telecontrol protocol. The connection is established via a SIM card and has its own access point to the mobile network (APN). At this access point, each SIM card installed in a GTPower Gear must authenticate itself to join the closed user group for communication with the control system.

The basic configuration of the GTPower Gear consists of three elements:

- PLC (Programmable Logic Controller): A small computer, which processes and encrypts the raw operating data of the installation.

- Modem: Provides a communications link between the remote unit and the control system.

- Antenna: Amplifies the signal reception and can be located up to 35 m from the GTPower Gear if necessary, for example, on the roof of a building.

If the GTPower Gear is installed on site, the plant becomes part of the Virtual Power Plant. It can now send all the data that forms the basis for calculating the optimum way it should be operated directly to our control system. Even though we are able to control the networked units via the GTPower Gear, the individual units remain independently owned and operated.